In the fast-evolving world of electronics, the demand for high-performance components has never been higher. One of the key players in this landscape is the HDI (High-Density Interconnect) Printed Circuit Board. These advanced circuit boards offer numerous advantages that cater to the needs of modern devices, ranging from smartphones to sophisticated medical equipment. This blog explores the key benefits of HDI printed circuit boards, emphasizing why they are becoming essential in contemporary electronics.

Increased Component Density

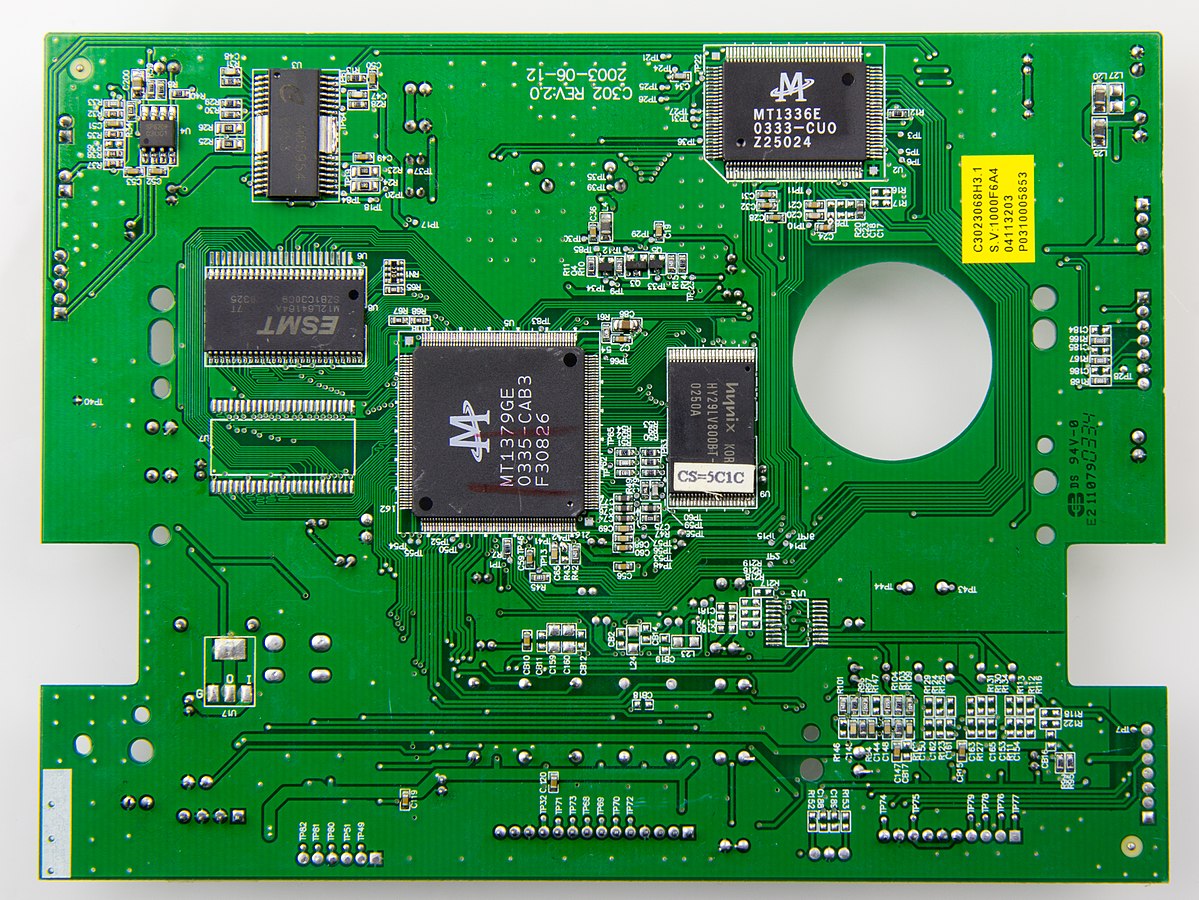

One of the standout features of HDI Printed Circuit Boards is their ability to accommodate a higher density of components compared to traditional PCBs. By utilizing microvias and finer traces, HDI boards can fit more components into a smaller footprint. This increased density is particularly beneficial for compact devices like smartphones and tablets, where space is limited.

Advantages of Increased Density:

- Miniaturization: HDI boards allow for the development of smaller, lighter devices without sacrificing performance.

- Enhanced Functionality: More components can lead to additional features and functionalities within the same device space.

Improved Electrical Performance

The design of HDI printed circuit boards contributes to superior electrical performance. With shorter traces and reduced impedance, HDI boards minimize signal loss and interference, which is crucial for high-speed applications.

Key Factors in Electrical Performance:

- Signal Integrity: Enhanced signal integrity allows devices to function reliably at high frequencies, making HDI boards ideal for applications like RF devices and high-speed computing.

- Thermal Management: The compact design of HDI boards also aids in better thermal management, reducing the risk of overheating in densely packed devices.

As technology advances, the need for improved electrical performance in devices is paramount. To discover more about the electrical advantages of HDI boards, click this link here now.

Cost-Effectiveness in Production

While HDI printed circuit boards may initially seem more expensive due to their advanced technology, they often prove to be cost-effective in the long run. The ability to fit more components in a smaller area can reduce the overall size of the final product, leading to lower material costs and simplified assembly processes.

Cost-Effectiveness Benefits:

- Material Savings: With HDI technology, manufacturers can use fewer raw materials, such as copper and substrate, which can lead to significant cost savings.

- Efficiency in Assembly: The compact design can streamline assembly processes, reducing labor costs and time.

By understanding the cost advantages, manufacturers can make informed decisions about adopting HDI technology in their products.

Enhanced Reliability and Durability

HDI printed circuit boards offer superior reliability and durability compared to traditional boards. The advanced manufacturing processes used in creating HDI boards, such as laser drilling and sequential lamination, result in a more robust and resilient product.

Reliability Factors:

- Reduced Risk of Failure: HDI boards are less prone to mechanical failure due to their compact construction and quality materials, making them ideal for critical applications in medical and aerospace industries.

- Longer Lifespan: The durability of HDI boards contributes to a longer lifespan for devices, reducing the frequency of repairs and replacements.

Ensuring the reliability of electronic devices is essential for manufacturers, particularly in sectors that require stringent safety standards.

Design Flexibility

Another significant benefit of HDI printed circuit boards is their design flexibility. Manufacturers can create intricate and complex layouts that meet the specific needs of modern electronic devices. This adaptability allows for innovative designs that were previously impossible with traditional PCB technology.

Benefits of Design Flexibility:

- Custom Solutions: HDI technology supports various configurations, enabling the design of bespoke solutions tailored to particular applications or industries.

- Integration of Advanced Technologies: As technologies such as IoT (Internet of Things) and wearable devices evolve, HDI boards can accommodate new components and technologies, ensuring devices remain cutting-edge.

This flexibility is crucial in an industry where consumer preferences and technological advancements change rapidly.

Better Heat Dissipation

Heat management is a crucial aspect of modern electronic devices, especially those that perform high-intensity tasks. HDI printed circuit boards excel in heat dissipation, making them ideal for applications that generate substantial heat.

Advantages of Enhanced Heat Dissipation:

- Thermal Pathways: The design of HDI boards allows for better thermal pathways, which helps dissipate heat more effectively than traditional boards.

- Reduced Risk of Overheating: Improved heat management contributes to the reliability and longevity of devices by reducing the risk of overheating.

In a market where device performance is paramount, the thermal advantages of HDI boards cannot be overstated.

Compatibility with Advanced Technologies

As the electronics industry embraces advanced technologies like 5G, artificial intelligence (AI), and machine learning, the demand for high-performance PCBs continues to rise. HDI printed circuit boards are well-equipped to support these technologies due to their ability to integrate sophisticated components and maintain high performance.

Compatibility Benefits:

- Future-Proofing Devices: By adopting HDI technology, manufacturers can future-proof their devices, ensuring compatibility with the latest advancements in technology.

- Scalability: HDI boards can easily scale to meet increased demands for performance, making them suitable for both consumer electronics and industrial applications.

Staying ahead of technological trends is vital for any manufacturer.

Conclusion

The benefits of HDI Printed Circuit Boards in modern devices are extensive, from increased component density and improved electrical performance to enhanced reliability and cost-effectiveness. As electronic devices continue to evolve, the demand for high-quality, high-performance components will only grow. By integrating HDI technology, manufacturers can not only enhance the functionality and longevity of their products but also ensure they remain competitive in a rapidly changing market.

For manufacturers looking to improve their electronic designs, understanding the advantages of HDI technology is essential. Whether you’re developing the latest smartphone, medical device, or advanced industrial equipment, HDI printed circuit boards can provide the performance and reliability needed to succeed.