Slip rings are essential devices used in various applications to enable the transmission of electrical signals, power, and data between stationary and rotating components. These ingenious devices have found their way into industries such as robotics, wind turbines, surveillance systems, and even amusement park rides. If you’re new to slip rings or seeking to expand your knowledge, this comprehensive guide will walk you through everything you need to know about how to use a slip ring effectively and efficiently.

How to Use a Slip Ring: Understanding the Basics

What is a Slip Ring, and How Does it Work?

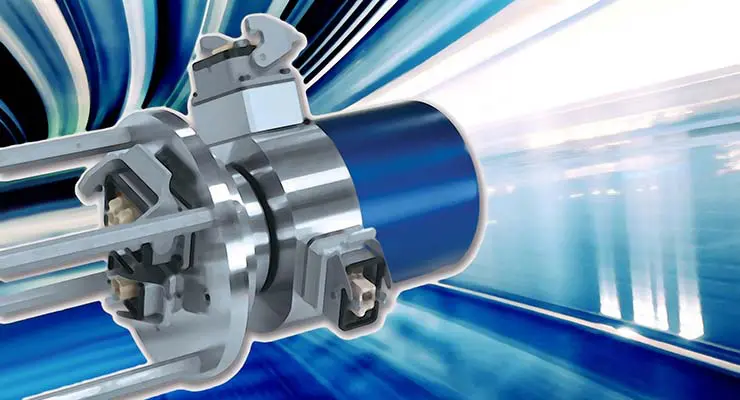

A slip ring, also known as a rotary electrical joint, is a vital electromechanical device that allows the transfer of power and signals from a stationary to a rotating structure. It consists of two main components – the stationary part, called the stator, and the rotating part, known as the rotor. The stator remains fixed to the stationary component, while the rotor spins with the rotating part.

Inside the slip ring, conductive brushes maintain contact with conductive rings or tracks, which allows the transmission of electrical signals and power between the stationary and rotating parts. This ingenious design enables uninterrupted data and power transfer, making slip rings crucial in various applications.

The Different Types of Slip Rings

There are several types of slip rings available, each tailored to suit specific applications. Some common types include:

- Through-Hole Slip Rings: These slip rings have a central hole that allows other components like shafts or cables to pass through the center, making them ideal for applications requiring a rotating shaft.

- Capsule Slip Rings: Compact in design, capsule slip rings are perfect for applications with limited space and offer various circuit options.

- Pancake Slip Rings: Flat and compact, pancake slip rings are suitable for applications where vertical space is restricted.

- Mercury Slip Rings: These specialized slip rings use mercury as the conductive medium, ensuring low electrical noise and minimal friction.

- Fiber Optic Slip Rings: In applications requiring optical signal transmission, fiber optic slip rings provide an efficient solution.

- Pneumatic Slip Rings: Used in applications that involve the transfer of pneumatic or hydraulic signals alongside electrical signals.

How to Install a Slip Ring: Step-by-Step Guide

Installing a slip ring properly is crucial to ensure smooth and efficient operation. Here’s a step-by-step guide to installing a slip ring correctly:

- Gather the Necessary Tools: Before starting the installation, make sure you have all the necessary tools, including screwdrivers, pliers, and any other specific tools mentioned in the slip ring’s manual.

- Read the Manual: Familiarize yourself with the slip ring’s manual, as different slip rings may have specific installation instructions.

- Prepare the Surface: Ensure that the mounting surface is clean, flat, and free from any debris that could interfere with the installation.

- Secure the Stator: Fix the stator to the stationary part of the application using appropriate fasteners.

- Connect Wires and Cables: Connect the wires and cables from the stator to the electrical system following the manufacturer’s guidelines.

- Install the Rotor: Attach the rotor to the rotating part of the application, ensuring proper alignment with the stator.

- Test the Slip Ring: Once installed, perform a functionality test to ensure all connections are secure and the slip ring operates smoothly.

Tips for Maintaining and Caring for Slip Rings

Regular Inspection and Cleaning

To maintain optimal performance and prolong the lifespan of your slip rings, regular inspection and cleaning are essential. Here are some tips for proper slip ring maintenance:

- Inspect the slip ring regularly for signs of wear, damage, or contamination.

- Clean the slip rings periodically using a lint-free cloth or a soft brush to remove dust and debris. Avoid using abrasive materials that could damage the slip ring’s surface.

- If the slip ring is contaminated with oil or grease, use an appropriate cleaning solution recommended by the manufacturer on Proper Tech Zone.

Lubrication

Proper lubrication is crucial to ensure smooth operation and minimize wear and friction. Here are some key points to consider when lubricating slip rings:

- Use a high-quality lubricant recommended by the slip ring manufacturer.

- Apply the lubricant sparingly and evenly, ensuring it reaches all the necessary contact points.

- Avoid using excessive lubrication, as it can attract dust and debris, leading to potential performance issues.

Environmental Considerations

Slip rings are often exposed to various environmental conditions, which can affect their performance. Here are some environmental considerations to keep in mind:

- Protect the slip ring from excessive moisture, humidity, and corrosive substances.

- If the application operates in extreme temperatures, ensure the slip ring is designed to withstand those conditions.

- Consider using protective covers or enclosures to shield the slip ring from environmental factors.

Conclusion

Understanding how to use a slip ring is crucial for various applications that require the transmission of power and signals between stationary and rotating components. By following the installation steps, implementing proper maintenance, and considering environmental factors, you can ensure optimal performance and longevity of your slip rings. Remember to choose the right type of slip rings for your specific application requirements, and consult the manufacturer’s guidelines for best practices.